South African Telescope to Sport UW-Madison Eyewear

SSEC engineers are constructing an innovative upgrade to the Robert Stobie Spectrograph (RSS), the primary optical instrument on the Southern African Large Telescope (SALT). This effort provides essential support to PI Marsha Wolf, of the UW-Madison Department of Astronomy and the Washburn Astronomy Laboratories. The SALT is the largest single optical telescope in the southern hemisphere and among the largest telescopes in the world.

Currently, the RSS is equipped with a visible instrument (VIS) observing wavelengths of 320-900 nm. This upgrade will add a Near Infrared instrument (NIR) to extend observations out to 1700 nm. The NIR will weigh around 445 kilograms and sit on six pillars on the same frame that support the VIS above the mirror.

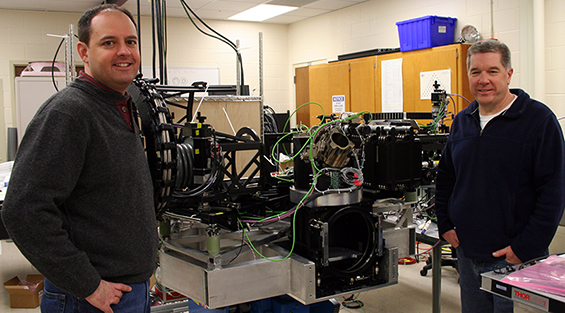

Project Manager Mark Mulligan, SSEC, (left) and Control System Engineer Ron Koch, contractor for SSEC (right) with the Near Infrared instrument. Photo credit: SSEC.

Project Manager Mark Mulligan (SSEC) explains, “The SALT is an 11-meter telescope consisting of a multi-faceted mirror which is set at a fixed angle of 37˚ from the zenith, and rotates in azimuth for observations. This project will upgrade the RSS to a dual-beam spectrograph that operates both in the visible and the near infrared ranges.”

When the NIR instrument is added to the existing VIR, the combination of the two instruments will provide simultaneous visual and infrared observations of the same target object, a capability unique to the SALT.The RSS is positioned 13 meters above the mirror. As the Earth rotates, it is the RSS that moves its focal point across the surface of the mirror, thus allowing very high time resolutions in image gathering — as fast as one image every 0.1 seconds in some modes. Couple this high-speed image gathering with sufficient sensitivity to measure a candle’s flame on the surface of the Moon, and the RSS-equipped SALT telescope is capable of studying objects as close-by as asteroids in near-Earth orbits, and galaxies in the far reaches of the Universe.

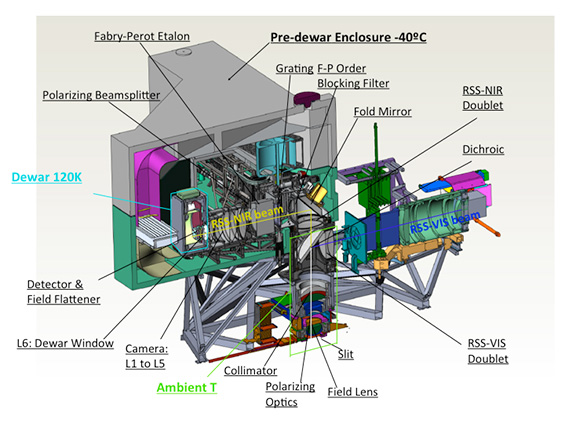

The RSS NIR/VIR Assembly. The light captured by the telescope mirror enters at the bottom of the assembly via the Field Lens, and is split by a dichroic mirror into two beams: visible and near infrared.

As the beam is refracted to the Near Infrared (NIR) instrument, it may pass through a wave-length limiting filter, a spectrum-creating grating, or a wave-length measuring Fabry-Perot etalon, depending on the data desired.

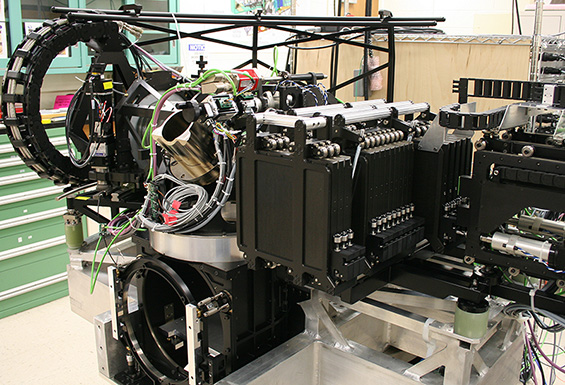

A filter is selected and inserted from a magazine of twelve filters. Typically, only one filter is used at a time, but any of the twelve filters can be inserted or removed remotely via the control computer. The filters rest in two magazines, one holding nine filters, one holding three, which can be reconfigured relatively easily.

The RSS NIR assembly without its enclosure (note filter magazines center) and insert/extract mechanism (lower right). Also note curved, tracked cable guide (left). Photo credit: SSEC.

“The scientists can plan ahead,” Mulligan says. “By having twelve filters on line, so to speak, and only rearranging and swapping out the filters occasionally in the magazines, much time and effort can be saved.”

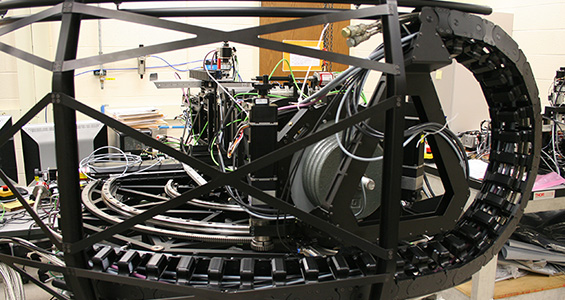

The RSS NIR assembly without its enclosure. Note curved, geared track (lower left) for precise rotation of the camera/Dewar. Also note segmented cable guide that not only guides and shields cable during movement, but also flexes around a curve to follow device movement. Weights simulate the mass of the Dewar. Photo credit: SSEC.

“One of the many design complications that we had to address,” Mulligan says, “is the fact that we are working in the infrared range. Essentially we are sensing differentials in heat, very tiny differentials since we dealing with signal obtained from so far away. Any residual heat in the instrument itself would skew our data.”

The entire RSS is enclosed in a refrigerated housing, the interior of which is kept at -40˚C (-40˚F). But that is not cold enough to ensure accurate data capture from the camera. The camera itself is enclosed in a vacuum-sealed Dewar container kept at 120˚K (-153˚C or -244˚F).

“A complicating factor,” Mulligan adds, “is the fact that with the Dewar at 120˚K and the entire instrument at -40˚C, the exterior of the instrument housing will get cold as well. The instrument sets on supports directly above the mirror lens and any condensation on the outside of the enclosure will drip down onto the mirror. So we actually heat the exterior of the enclosure back up to ambient temperature.”

In addition, the NIR must be able to move through a 55˚ arc within the frigid air of the enclosure. Any cabling that leads to and from the camera, such as power or data cables, needs to be flexible over long periods of high usage and at very low temperatures.

Ron Koch, the Control System Engineer, had to find the proper cabling to overcome this issue. “We needed a cable that could handle not only the continuous flexing as the mechanism continually moves, but also the -40˚C temperature inside the enclosure. We found cables that could handle one thing or the other, but it was hard to find any that handled both. Add to that the fact that we would only be purchasing a relatively small amount of cable, a hundred feet instead of thousands.”

Another problem with cables that flex continuously is that twisted wire pairs can have all of the twists worked toward one end of the cable. Eventually the pairs twist around themselves.

“They can end up looking like a snake that swallowed a rat,” Koch laughs. “And we also wanted twisted quad cabling, which makes a thinner cable that can be flexed at a tighter bend radius.”

Koch finally found a vendor, Helukable, that could handle the exacting specifications.

“We did a 75,000 cycle test of Helukable’s product,” Koch says. “We dissected the used cable and found that it had a little bit of wear on the polyurethane jacket, but that it easily passed the test.”

Nine of the 14 individual mechanisms that make up the NIR have all been built and tested. The next step is to integrate them into the device and make sure that they all function properly together.

“The design process of the RSS NIR instrument began in early 2008,” Mulligan says. “We have been building and assembling for the last 15 months. The instrument installation is dependent upon an upgrade to the telescope, but we hope it will be in about two years. By contributing this instrument to the telescope, the Department of Astronomy becomes one of the major shareholders in the SALT consortium. There will be x amount of science viewing per year; they will get a percentage of that.”

The Robert Stobie Spectrograph is named in honor of the late Director of the South African Astronomical Observatory. The SALT telescope has been operational since 2005. Visit the SALT Webcams.